Introduction

TOP-LINK Smart Assembly Solution focuses on high-speed automated production, delivering high output, stable operation, and enhanced safety. Specifically designed for the pharmaceutical industry's pre-filled syringes, auto-injectors, safety devices, and high-volume consumer goods, it adapts to diverse product lines and complex production requirements. This solution shortens innovation cycles, helps businesses enhance competitiveness, and enables efficient, stable mass production.

Easy Operating

Compact Footprint

Easy Maintenance

Versatile & Flexible

Online Changeover Development

Integrated Component Combination

Feartures

-

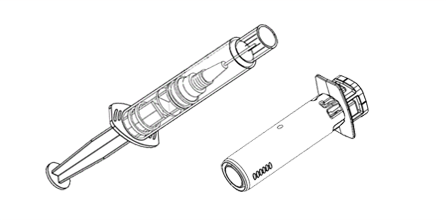

PFS Safety Devices Assembly This solution incorporates automatic feeding for passive safety devices, automatic sorting and feeding for active safety devices, automatic feeding of pre-filled syringes, and assembly functions for pre-filled syringes with safety devices. It also features visual inspection and automatic rejection mechanisms, reliably ensuring high-quality output with a high pass rate.

-

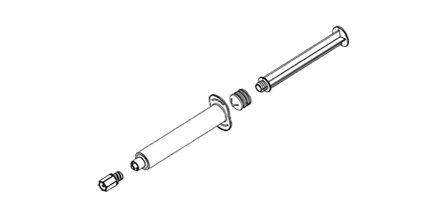

PFS Labeling and Assembly This solution integrates an automatic syringe barrel denesting system with an automatic plunger rod assembly machine for pre-filled syringes. It automatically performs barrel denesting, plunger rod feeding, booster assembly, torsion rod assembly, safety device assembly, and labeling. Servo-controlled precision torque ensures the rubber stopper remains stationary during rod rotation.

-

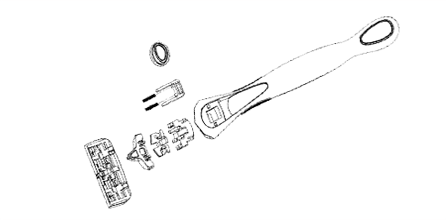

Two Blade Razor Head Assembly The proposed solution primarily involves upgrading the single blade razor head assembly to a two-blades head version. The process includes: Upper cover feeding, Upper cover assembly and status detection, Blade 1 assembly, Spacer assembly, Blade 2 assembly, Base feeding, Base installation, Base assembly status inspection, Cold riveting, Part removal, Visual inspection, Product discharge.