Functions

This equipment is specifically designed for assembling pre-filled syringes with safety devices. It integrates automatic feeding of passive/active safety devices, automated supply of pre-filled syringes, and precise assembly functions. Equipped with a vision inspection system for real-time quality control, combined with an automatic rejection mechanism to accurately screen out defective products, it effectively ensures high product quality and pass rate. Suitable for efficient and stable production demands of pre-filled syringe safety devices.

Features

High-Speed Stability: 400 pcs/min. output capacity, with precision cam curves ensuring reliable continuous operation.

Flexible Adaptability: Supports multi-specification switching with simple and efficient changeover procedures.

Long-Life Transmission: QPQ surface-treated gears deliver wear resistance, durability, and smooth operation.

Compact Layout: Streamlined structure minimizes footprint for easy cleaning and maintenance.

Intelligent Control: Integrated level alarms and vision inspection (compaction/false triggers) enhance yield rates.

Precise Marking: Equipped with international-standard marking systems for accurate identification.Compact Layout: Streamlined structure minimizes footprint and facilitates · cleaning/maintenance.

Intelligent Control: Integrated material level alerts and vision inspection (compaction/false triggers) enhance yield rates.

Precise Marking: Equipped with international-brand label printers to ensure coding and labeling quality.

Power-Off Resumption: Absolute encoder servo motors enable restart without homing, minimizing downtime.

Technical Specs

Parameter | Value |

Model | SD 400 |

Control System | Siemens PLC |

Speed | 360 pcs/min. |

Power Supply | 38V50HZ/3P+N+PE |

Box Type | Syringe OD 6–15 mm |

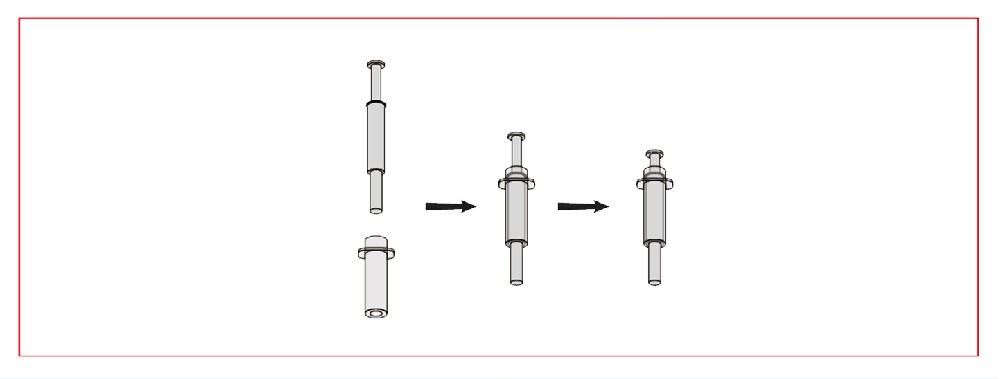

Process Flow Diagram

Hot Tags: