Functions

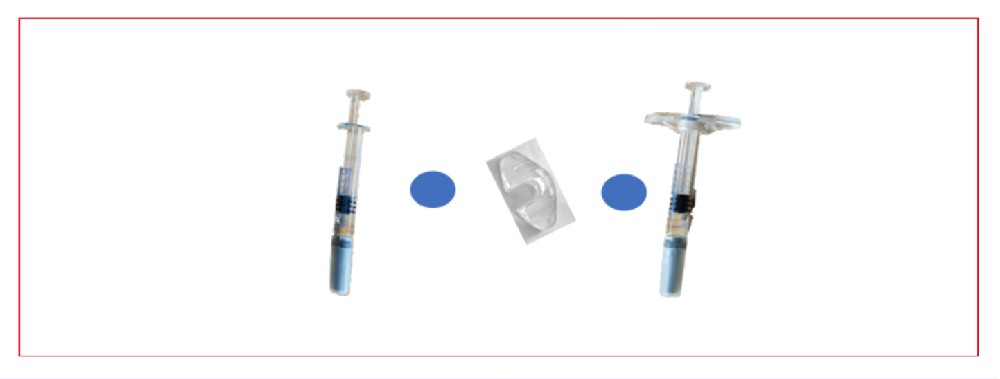

This equipment automates the assembly of pre-filled syringe booster (finger rests), enhancing injection control and packaging quality. It achieves a high-speed production capacity of 200 units per minute, utilizing continuous gear pressing to ensure precision. The tabletop design offers a clean layout for easy maintenance and quick changeovers. Equipped with a multi-turn absolute encoder servo motor, it requires no origin search upon power-on/restart. Supporting bus control for efficient operation and maintenance, it boosts quality and productivity in medical consumables manufacturing.

Features

High-efficiency output: Up to 200 pcs/min. to meet large-scale production demands.

Precision and stability: Continuous gear-pressing technology ensures high assembly accuracy and operational stability.

Easy Cleaning and Maintenance: Countertop layout ensures tidy aesthetics and facilitates daily cleaning and equipment upkeep.

Flexible Adaptability: Simple changeover operations enable rapid response to varying product specifications.

Smart Resumption: Multi-turn absolute encoder servo motors retain position memory during power loss, eliminating the need to return to origin upon restart.

Convenient Operation & Maintenance: Bus control system streamlines maintenance procedures and minimizes downtime.

Technical Specs

Parameter | Value |

Model | ZT 150 |

Speed | 150 pcs/min. |

Detection and Rejection | Sensor detection |

Power Supply | 38V, 50Hz |

Sorting Method | Sorting Method |

Process Flow Diagram

Hot Tags:

Previous

no more!