Functions

This machine achieves a fully automated packaging process (feeding/box opening/box loading/box sealing/reject sorting) with a compact, easily adjustable structure. It features a flip-up safety guard and offers optional hot-melt adhesive box sealing. The small box hopper provides ≥15 minutes of continuous operation, vacuum suction cups prevent crushing, and the pull-out design enhances maintainability. Supports rapid changeovers within 20 minutes. Features fault alarms, finished product counting, and an industrial PC control system to ensure synchronized mechanical and electrical operation.

Features

Safety-oriented ergonomic design

Flexible adaptability to meet diverse box sealing requirements

Small box hopper provides continuous feeding for ≥15 minutes, boosting production efficiency

Precision box protection technology ensures finished product quality

Efficient changeover: model switching ≤15 minutes

Equipped with fault display, alarm, and finished product counting functions for enhanced reliability

Industrial PC system achieves perfect synchronization between mechanical and electrical movements

Technical Specs

Parameter | Value |

Model | XSC100 |

Operation Type | Intermittent |

Packaging Type | Blister/Bottle |

Closure Type | Tongue Insert with Hot Melt Adhesive |

Max. Output | 100 boxes/min. |

Pitch | 180mm |

Carton Dimensions | 70mm-200mm (L) x 25mm-140mm (W) x 15mm-85mm (H) |

Machine Dimensions | 4500 mm (L) x 1700 mm (W) x 1600 mm (H) |

Machine Weight | 2000kg |

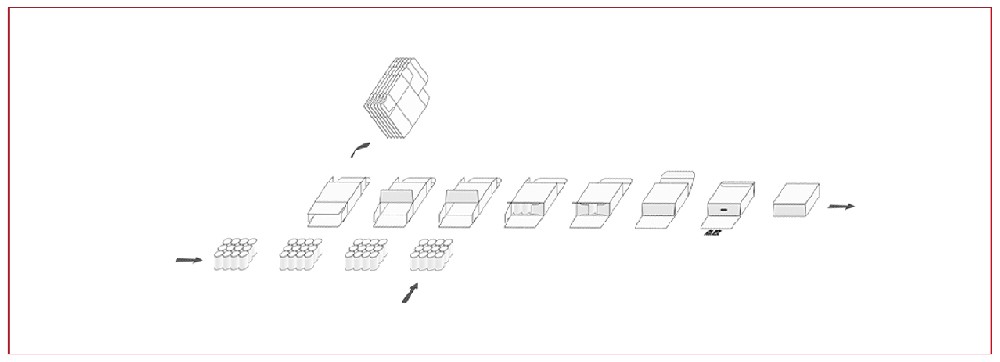

Process Flow Diagram

Hot Tags: